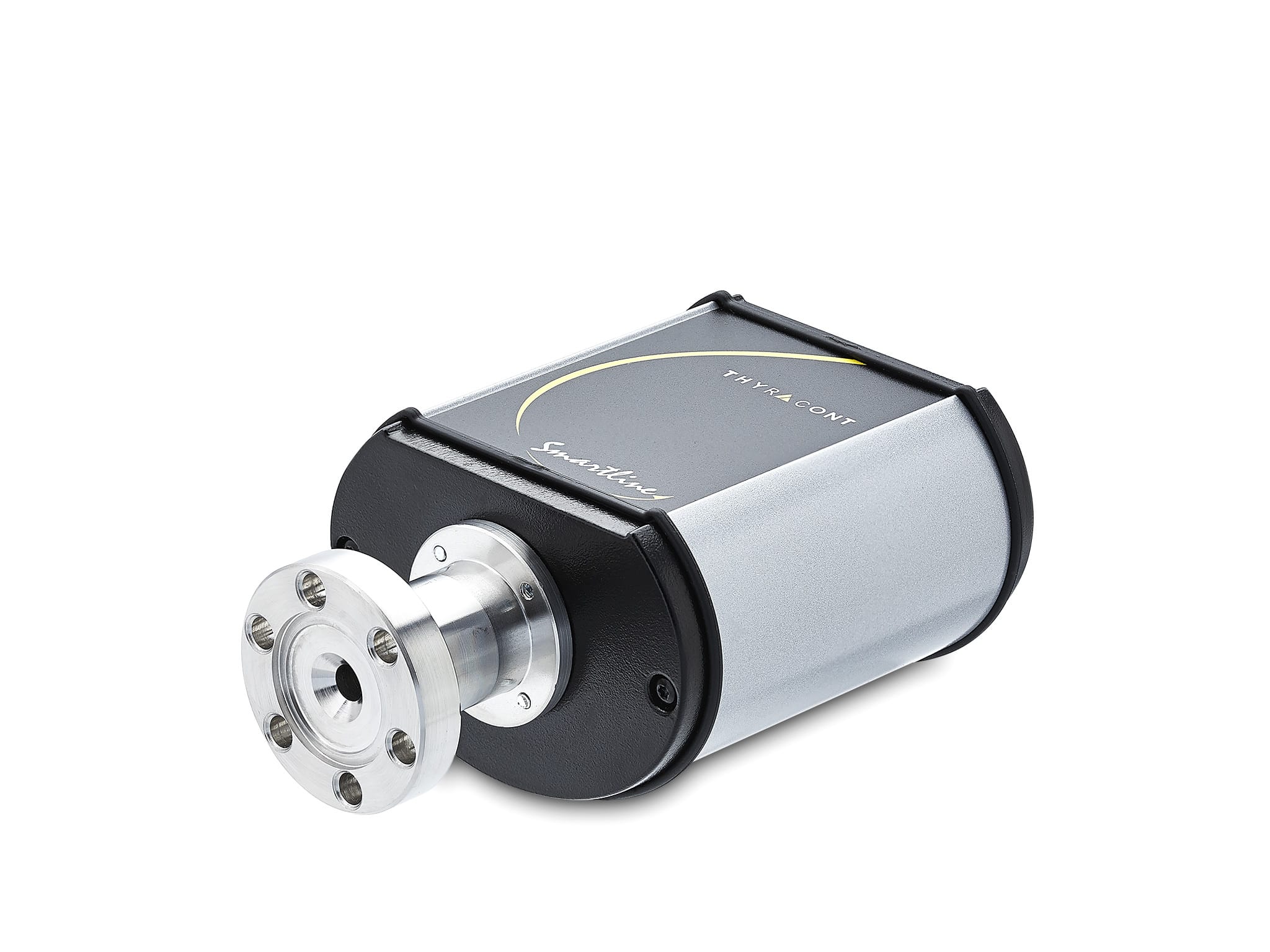

VCL Vacuum Transducer for Loadlocks ● abs. 1200 to 5e-4 mbar ● rel. -1060 … +340 mbar ● PtRh ● digital

€ 701.00 – € 1,044.00 excl. VAT and transport costs

The digital vacuum transducer VCL was purpose-developed for load lock applications. The metal sealed vacuum gauge works with a multi sensor technology and combines two piezo sensors with a pirani sensor. So absolute pressure in the range 1200…5e-4 mbar and the pressure relative to the environment in the range of -1060 … +340 mbar are measured.

The digital vacuum transducer VCL was purpose-developed for load lock applications. The metal sealed vacuum gauge works with a multi sensor technology and combines two piezo sensors with a pirani sensor. So absolute pressure in the range 1200…5e-4 mbar and the pressure relative to the environment in the range of -1060 … +340 mbar are measured.

Overview Smartline vacuum transducers:

- Variety of interfaces: Digital RS485 interfaces plus 0-10 V output signal, EtherCAT or PROFINET. The Bluetooth adapter SLKBT enables wireless communication

- Industry 4.0: All Smartline transducers offer a series of parameters for preventive maintenance. PROFINET transducers are able to communicate with OPC UA servers and support MRP

- Exchangeable sensor heads: Is an easy job, independent of the gauge manufacturer and without programming effort. If the existing cables shall further be used, suitable adapters (e. g. FCC68) will be available.

- Optional display: Large LCD display (exc. EtherCAT, PROFINET)

- Easy adjustment: Readjustment of zero and atmosphere by push-button or interface

- LEDs: For device status and switch points

- Scaleable output characteristics: The 0-10 V output signal can be scaled according to the required output characteristics. Thus an exchange of existing vacuum gauges is easily, independent of the manufacturer and without programming effort possible. If the cable needs to remain but the transducer should be changed adapters (e. g. FCC68) are available.

- UHV suitable: Metal sealed stainless steel sensor cell,suitable for UHV applications (He leackage rate <5e-10 mbar l / s)

- Relay switch points: Two independent, potentialfree relay switch points (exc. EtherCAT, PROFINET)

- Robust: Resistant, EMC compatible metal housing, protection class up to IP54

- Controller: Expansion with 2 channel controller VD12 or 4 channel controler VD14 possible

- VacuGraphTM software: For visualisation, analysis and storage of measuring data

Overview VCL vacuum transducer for load locks:

- Integrated Multi Sensor System: Two piezo diaphragm sensors to monitor chamber pump-down and vent-up; Pirani sensor measuring down to 1e-4 mbar controls low-pressure transfer between loadlock and process chamber minimizing particle events

- On the point: Differential pressure output for precisely triggering door-open function

- Precise: High accuracy, optimal resolution and excellent stability

- Fast: Short response time of up to 40 ms

- Stable measurements: Due to optimized temperature compensation

- Measurements independent of gas type: Above 20 mbar

Do you have questions regarding our VCL vacuum transducers with Piezo/Pirani sensor for corrosive media? We will be pleased to assist.

Attention: If the Smartline transducer is used without PLC, an SLN4 power supply will be required.

→ Go to all vacuum transducers of the Smartline | → Go to accessories for all Smartline vacuum transducers

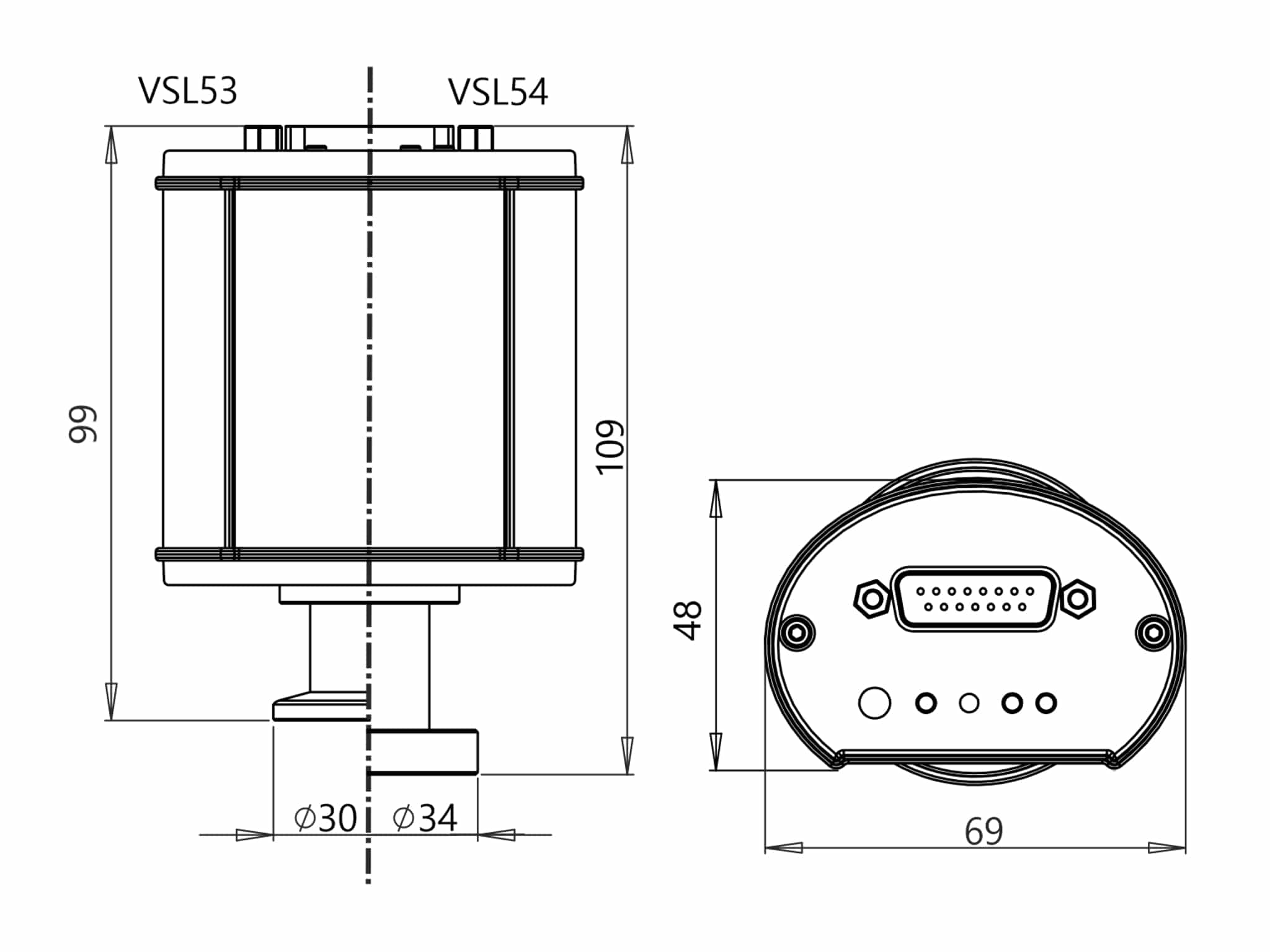

| Weight | 1.1 kg |

|---|---|

| Dimensions | 25 × 16 × 9 cm |

| Measurement principle | Piezo-resistive / heat conduction Pirani (Pirani, depending on gas type) |

| Measurement range mbar | 1200 – 5e-4 mbar, Relative pressure -1060 … +340 mbar (depending on ambient pressure) |

| Measurement range Torr | 900 – 5e-4 Torr, Relative pressure: -795 … +255 Torr |

| max. overload | 4 bar abs. |

| Accuracy | Absolute: 1200 – 10 mbar: 0.3 % f. s., 10 – 1e-2 mbar: 10 % f. r., Relative: 0.25 % f. spane |

| Repeatability | 1200 – 10 mbar: 0.1 % f. s., 10 – 1e-2 mbar: 5 % f. r. |

| Materials in contact with vacuum | Stainl. steel 1.4307, platinum/rhodium, nickel, glass, gold, silicon oxide |

| Response time | 40 ms |

| Operating temperature | +5…+60°C (Profinet +5…+50°C) |

| Storage temperature | -40…+65°C |

| Bake out temperature | |

| Voltage supply | 20 – 30 VDC |

| Power consumption | Max. 2.5 W, add. 0.8 W for EtherCAT / relays /LCD, 1.6 W for Profinet |

| Output signal | |

| Output Signal (detailed) | 0-10 VDC, min. 10 kΩ, measuring range 2.2 to 8.58 VDC, log. (Default) except for EtherCAT, Profinet |

| Serial interface | RS485: 9.6 kBd to 115 kBd, 8 databit, 1 stopbit, no parity, EtherCAT, Profinet |

| Switching output | 2x relay, potential free, 49 VAC / 2 A or 30 VDC / 2 A, max. 60 VA except for EtherCAT, Profinet |

| Electrical connection | RS485/0-10V: SubD, 15-pole, male, RS485/EtherCAT/Profinet: 1x M12 A / 2x M12 D, female |

| Vacuum connection | DN 16 ISO-KF (VCL53), DN 16 CF-F (VCL54) |

| Protection class | |

| Weight | 195 g (VCL53D) |

| Description | Data sheet RS485 interface with 0-10 V, EtherCAT or Profinet | Manual D/DL RS485, 0-10 V | Manual E RS485, EtherCAT | Manual PN RS485, Profinet, until SNo 22xxxxxx | Manual PN RS485, Profinet, with SNo 23xxxxxx |

|---|---|---|---|---|---|

| VCL5X Vacuum transducer Loadlock Piezo/Pirani | |||||

| EtherCAT Communication Manual |

| How can I program parameters like switching points or gas type correctional factors? The Smartline vacuum transducers are programmed via their RS485 interface. They respond e. g. on type requests, measurement requests, adjustment commands and commands for gas type correctional factor. It is also possible to program both relay switchpoints of the gauge via RS485. |

| Is the measuring signal independent of the gas type within the rough vacuum range? Yes it is in the pressure range above 15 mbar. |

| Is the Pirani sensor protected against pollution and dirt? All Thyracont Pirani sensors are fitted with a cover which protects against basic condensation and pollution. If the sensors are used in an extremely polluted environment, it is advised to additionally either use an extension pipe, an elbow fitting, a cooling trap or a seal ring with a sinter filter. We recommend to keep the transducer continously switched on because a hot Pirani filament reduces the sensitivity against contamination. |

| Is it possible to clean the Pirani sensor? Depending on the type and intensity of the pollution, it is feasible to clean the sensor with isopropanol. In order to do so, you need to fill the measuring cell completely with isopropanol and let it rest for a few minutes. After removal of the fluid, it is necessary for the cell to completely dry out. Please note that if e.g. oil debris is baked onto the filament, it is very tough or even impossible to clean. |

| Do I have to mount the instrument into a specific position? The instruments can be mounted in every position. The best accuracy is achieved if the flange of the instrument is mounted horizontally because the instruments are calibrated in this position. It is not recommended to mount the sensor at the bottom of a pipe as condensate and dirt could be collected in the sensor cell. |

| How often do I need to recalibrate the compact vacuum meter? The period between calibrations depends on the specific application. Especially in cases of coatings and contaminations on the sensor-head or if it is used in extreme temperature conditions, readjust of the instrument can be neccessary. For quality assurance matters, we recommend to return the instrument for calibration every one or two years. We can offer a works calibration (article no. ADJCERT) or a DAkkS calibration (article no. DKDCERT). |

| Is it possible to exchange the sensor heads of the transducers? The exchangeable, pre-adjusted Smartline replacement sensors can be exchanged fast and easy by the user to assure best compatibility. Loosen the attachment screws around the head, exchange the sensor-head and reattach the attachment screws. After a heating-up phase of 15 minutes press the “Adjust” button, the sensor system and the electronics will be aligned automatically and the transmitter is ready to use. |

| What is the difference in applications between a cold cathode and a hot cathode gauges? Hot cathode transducers are mainly used for measurements where high precision (<15%) is needed. For measurements in the ultra-high-vacuum range down to 5e-10 mbar we also recommend our hot cathode. Cold cathode transducers are more durable in numerous applications and therefore relevant for environments where the sensor is exposed to dust, oil or other pollution. The cold cathode measuring cell can be partly disassembled and cleaned (e.g. with Scotch Brite). The VSM and VSI cold cathodes are not quite as precise as a hot cathode transducer. However, the resolution and precision of both gauges is still excellent for a cold cathode sensor (<25%). If necessary the sensor heads of all transducers can be changed to assure a high plant availability. |

| Is it possible to clean the sensor head of the VSM? Yes, it is possible to partly disassemble the sensor head and clean it with Scotch Brite. Metallic debris and minor pollution can be cleaned like this easily. |

| Is it possible to clean the sensor head of the VSH? Hot cathode sensors are not suited for cleaning. |

Related products

-

Compare

VCP Vacuum Transducer ● Pirani ● for corrosive media ● 1000 to 5e-4 mbar ● digital

€ 454.00 – € 793.00 excl. VAT and transport costs View Product -

Compare

VD85 Compact Vacuum Meter ● Piezo/Pirani ● 1200 to 5e-4 mbar

€ 699.00 excl. VAT and transport costs View Product -

Compare

VCR Vacuum Transducer ● Piezo/Pirani ● PtRh Filament ● 1200 to 5e-4 mbar ● digital

€ 683.00 – € 1,030.00 excl. VAT and transport costs View Product -

Compare

VD81 Compact Vacuum Meter ● Piezo ● 1600 to 1 mbar

€ 435.00 excl. VAT and transport costs View Product

Further relevant products

-

SLKBT Interface Converter RS485-Bluetooth

€ 167.00 excl. VAT and transport costs View Product -

VGR VacuGraph software for Windows, MacOS and Linux

€ 212.00 – € 424.00 excl. VAT and transport costs View Product -

SLZUB Accessory Set ● for Smartline Vacuum Transducers

€ 366.00 excl. VAT and transport costs View Product -

SLN4 Plug-in power supply ● 24 V ● for Smartline Transducers

€ 110.00 excl. VAT and transport costs View Product