Benefits VCR at a glance

- Wide measuring range due to combination sensor Piezo / Pirani

- Suitable for demanding applications with aggressive media due to platinum rhodium filament

- High accuracy and resolution in rough and fine vacuum

Laser beam welding in vacuum

In a lot of sensor housings lids or metal membranes are welded in, to ensure a leak tightness or to protect the measuring technique of environmental influences. Also, in other applications connection elements for high pressures applications need to be welded on housings, to enable the functionality of the sensors.

Challenge

Inner pressures of sensors over 400 bar are not rare and partially a tightness of 1e-9 mbar l/s has to be ensured. Therefore, the welding seams need to be of highest quality. The functionality of the sensor must not be affected, especially the size accuracy of the required sensor contour is of high meaning. The welding of various materials requires different pressures levels. In order to achieve reproduceable results of highest quality, the pressures levels need to be controlled precisely. For this reason, the used vacuum transducers need to fulfil highest requirements to accuracy and reliability.

Solution

The vacuum transducer VCR53E is used for absolute pressure measurement in gaseous media in the range of 1.0e-4 1200 mbar. The transducer type VCR with platinum-rhodium filament is due to its robustness suitable for the usage in a lot of applications. The VSR is equipped with a metal sealed combination sensor of the type piezo/Pirani and temperature compensated, thus it is especially suitable for laser beam welding.

The relatively smooth surface of the platinum-rhodium filament reduces coatings of welding fume emissions of other contamination and ensures proven an especially long lifetime of the filament. The metal sealed measuring cell with robust spiral coil and stainless stell flange make the transducer especially durable. The process security of the laser beam welding in vacuum is optimized and the maintenance charges are reduced at the same time.

References

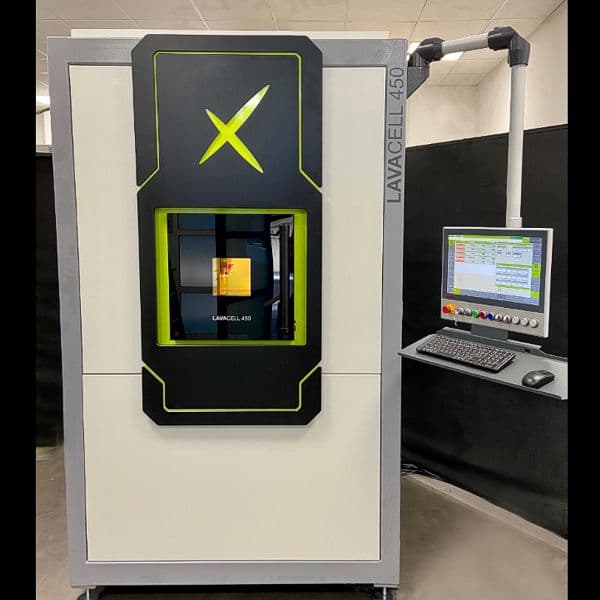

LaVa-X GmbH is specialized on the laser and electron beam welding of metalic materials and successfully works with Thyracont vacuum measurement instruments for years.