Benefits of VSP63DL at a glance

- Durable, elastic Pirani spiral coil filament

- Stable measurements due to optimized temperature compensation

- Integrated metal screen for protection against oil and solvent vapors

- Overpressure stability up to 16 bar

Benefits of VSM77D at a glance

- Wide range combi sensor Pirani / cold cathode

- Automatic control of the cold cathode by the Pirani, switch-on of cold cathode at low pressure increases lifetime, insensitive against inrush of air

- Excellent ignition behavior

- Low stray magnetic field

- Overpressure stability up to 16 bar

Thermomechanical material testing

With quantum computers, physicians hope to simulate all processes found in nature e. g. the primary origin of the universe and of life. Here, they still face big technical challenges, as quantum chips must be cooled down to temperatures close to the absolute zero-point and the components have to withstand extreme below zero temperatures. To analyse the components custom-developed measuring gauges with deep temperature option are required.

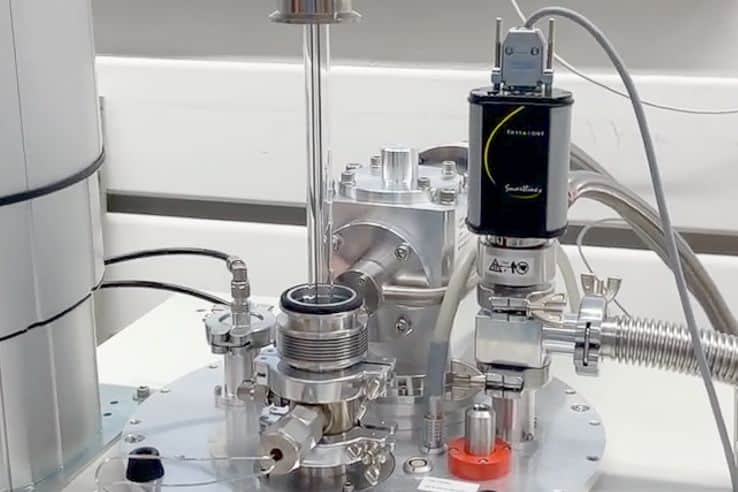

For this purpose, the Linseis Messgeräte GmbH developed the Cryo-TMA, a measuring gauge for thermomechanical materials testing. Analysing the components of a quantum computer. With 4 Kelvin the Cryo-TMA reaches a temperature of -269.15 °C and thereby nearly the absolute point-zero. The measuring gauge is mainly used for material characterization in space simulation.

Challenge

A clean inert gas atmosphere is generated for the process. In this environment a power based melting process can take place without the risk of contamination due to reactive gases, existing in the air, such as oxygen and carbon dioxide. The measuring chamber must be evacuated down to 1e-7 mbar.

Solution

For monitoring of the fore vacuum a Pirani vacuum transducer VSP63DL with integrated display is used. The high vacuum in the measuring chamber is controlled with the VSM77D vacuum transducer, a combination of Pirani and cold cathode. Due to the integrated Pirani sensor the cold cathode is only switched on at low pressures. This protecting the sensor from damage and thereby extending its service life. The measured values of both transducers are transferred and stored in the Linseis thermoanalysis software using their 0-10 V interface.

Source: Linseis Messgeräte GmbH, more details: YouTube