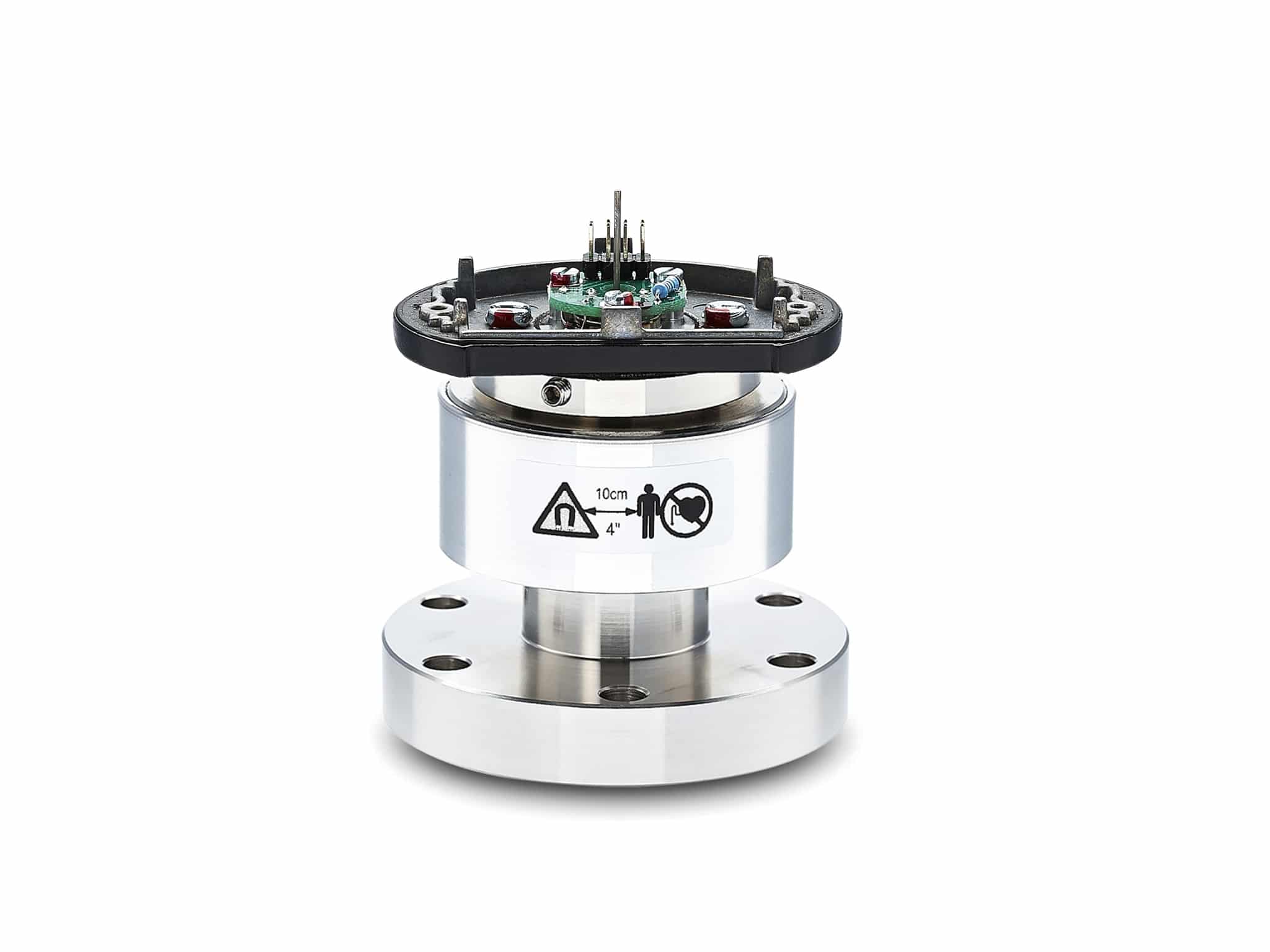

B_VSM replacement sensor ● Pirani/ Cold Cathode ● for Smartline VSM

€ 327.00 – € 381.00 excl. VAT and transport costs

Exchangeable sensor head for VSM7xxx (independent of interface options)

For models with serial no. 23000100 or higher

Further relevant products

-

CERT31P Inspection Certificate 3.1

€ 89.50 excl. VAT and transport costs View Product -

SLZUB Accessory Set ● for Smartline Vacuum Transducers

€ 366.00 excl. VAT and transport costs View Product