VTA Verfahrenstechnische Anlagen GmbH & Co. KG uses our compact vacuum meters to easily and flexibly monitor the vacuum in their distillation plants and to determine the leakage rate.

“We use Thyracont’s compact vacuum meters to measure and monitor the vacuum in our distillation systems and to determine the leakage rate. Their wide measuring range from 0.0005 mbar to over 1000 mbar is particularly important to us. Besides, the devices are very easy to operate and extremely flexible in use,” says Markus Widera, Project Manager for Laboratory and Pilot Plants at VTA Verfahrenstechnische Anlagen GmbH & Co. KG.

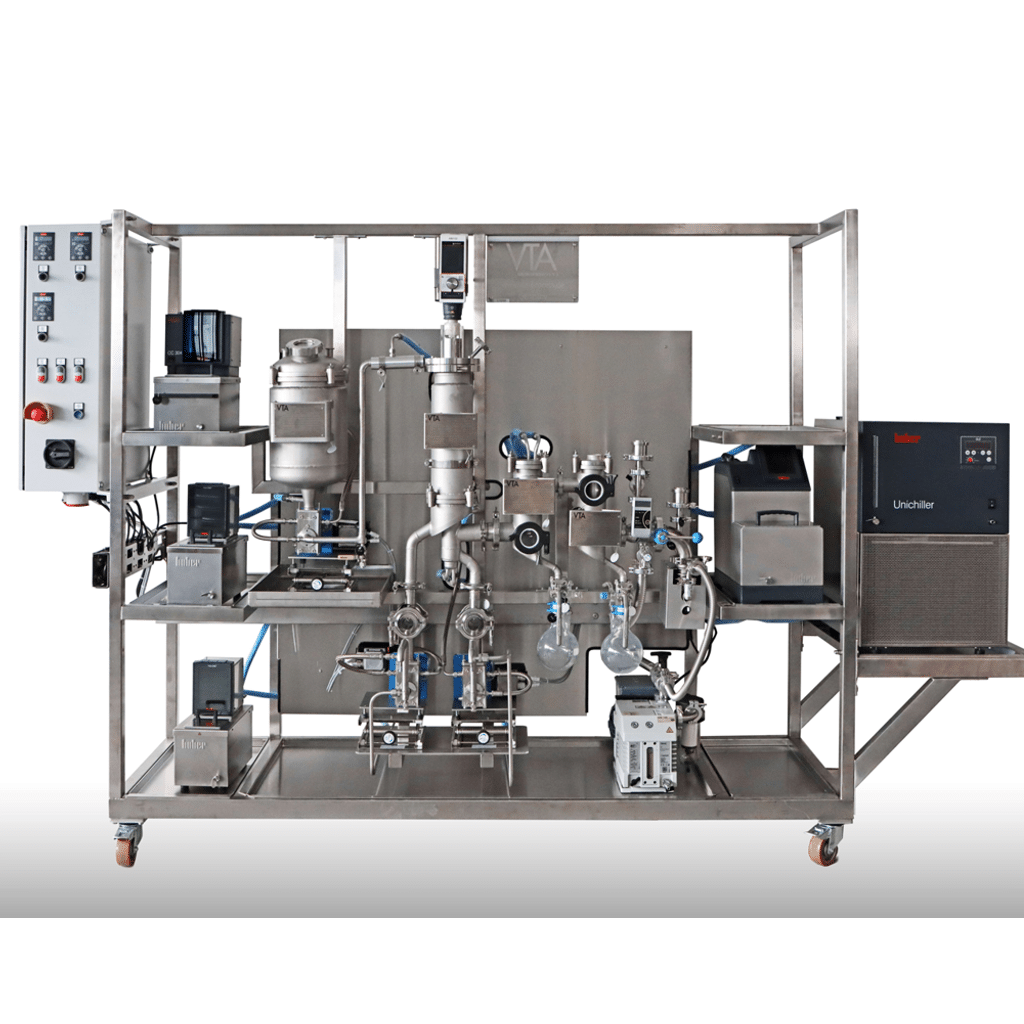

The company specializes in the production of thin-film and short-path distillation systems for thermal material separation. The plants are operated in the chemical, agrochemical, pharmaceutical, polymer and food chemistry sectors, among others. VTA also has its own test center for laboratory and pilot tests, e.g. to check the feasibility of the distillation task.

Short path distillation enables gentle separation of thermally sensitive product mixtures. By lowering the working pressure into the fine vacuum range, distillation takes place at very low temperatures. Depending on the type of system, the volume of the laboratory and pilot systems ranges from 1 to 50 liters. A pressure measurement is carried out over 30 minutes using the compact vacuum meter, the permissible leak rate is 0.1 mbar l/s, the achievable final pressure is at least 0.001 mbar.

The vacuum meters are also used in industrial thin film and short path distillation plants to carry out measurements in large containers of up to 50 m³. The data is read out via the associated PC software, provided with information about the system and stored for quality assurance purposes.

Article on digital vacuum meters (in German published in: Physik Journal Best Of, October 2023)

VTA Verfahrenstechnische Anlagen GmbH & Co. KG