Thyracont Vacuum Instruments is the first manufacturer of vacuum measurement technology offering transducers which comply with OPC UA, an open data transfer standard for industrial communication. OPC UA allows a safe data transmission from machine to machine or machine to PC, independent of manufacturer, programming language or operating system.

From now on all vacuum transducers of the product family Smartline™ with RS485 interface provide further parameters to support predictive maintenance, the proactive servicing of machines and appliances. Users can check the degree of sensor wear or corrosion, the time of the last adjustment and the operation hours. Thus, the service intervals can better be planned, if necessary appropriate spare parts ordered in time and systems run time optimized. All parameters are also available in the VacuGraph™-Windows®-Software from Thyracont.

As a next step, maintenance parameters can also be queried via the Profinet interface and consequently enable direct integration into an existing Profinet network with PLC, which can also take over the entire monitoring of the process.

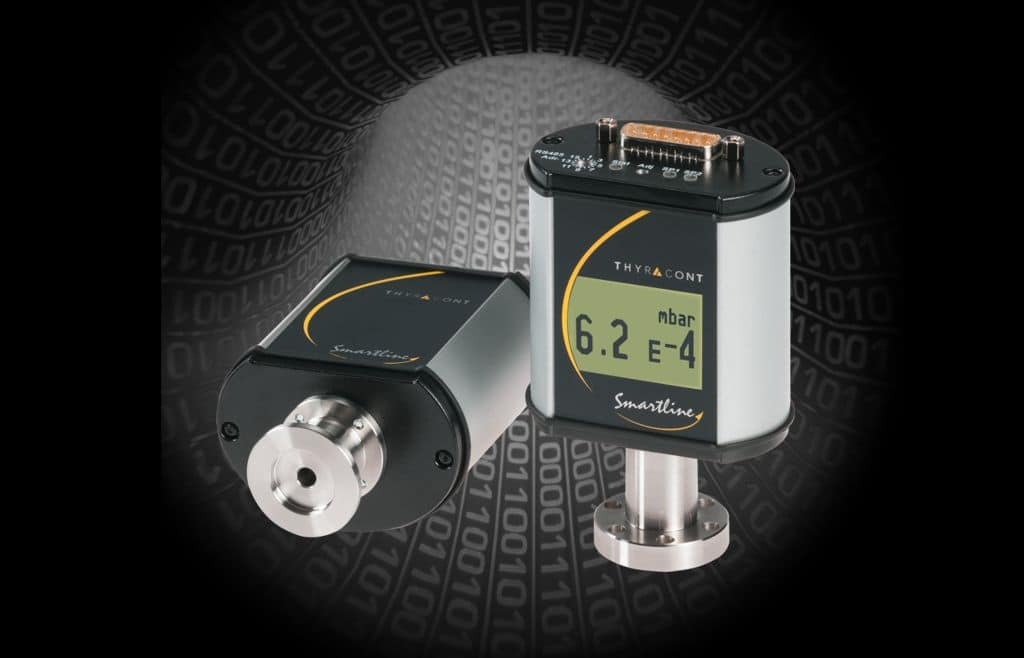

The digital Smartline™ transducers measure in range of rough down to high vacuum, offer outstanding reliability and precision for the control of industrial vacuum processes. Beside the classic analogue 0-10V output, digital interfaces like RS485, EtherCAT and Profinet allow intelligent connection to PLCs. Relay switch points and an optional, integrated display make the vacuum transducers flexible applicable.